Bore Alignment: Why Traditional Methods Are Falling Behind

Few alignment tasks demand the level of precision that bore positioning does. Across large turbines, even minor deviations in centerline position can have measurable effects—wearing down bearings, increasing vibration, and cutting into efficiency over time. Given the scale and complexity of these machines, achieving true bore alignment isn’t just about precision; it’s about repeatability and reliability.

For years, technicians have relied on a mix of optical instruments, micrometers, and wire-based methods to get the job done. These tools require patience, experience, and a steady hand—measuring offsets in fractions of a millimeter, compensating for sag over long spans, and manually interpreting results. But as turbine designs evolve and tolerances tighten, so do the demands on alignment methods.

Laser-based systems are increasingly taking on that role, offering a way to measure and adjust bores faster, with greater repeatability and less technician-dependent variability. But in a field where methods are time-tested and precision is non-negotiable, what does a shift in approach really look like?

Piano Wire Alignment: A Test of Precision and Patience

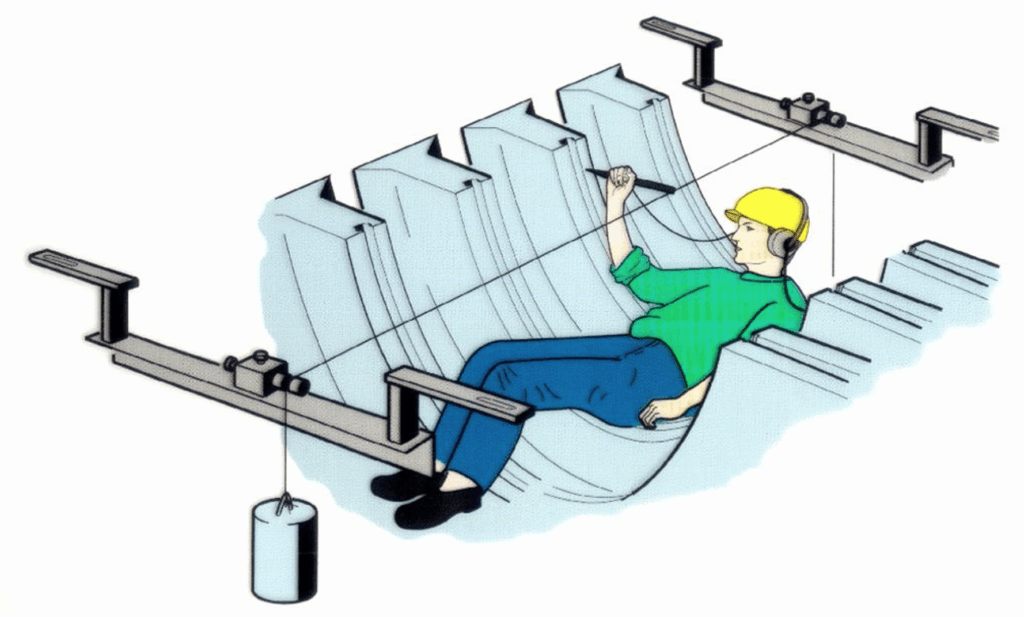

For decades, bore alignment has been a manual, methodical process. Piano wire, one of the longest-standing techniques, relies on a simple but demanding principle: stretch a thin steel wire through reference bores, measure deviations with micrometers, and adjust accordingly. In theory, it’s straightforward. In practice, it requires a technician’s full attention—and often, a fair bit of physical contortion.

Everything hinges on the wire being positioned perfectly. Tension weights help keep it stable, sometimes even submerged in oil to dampen vibration, and technicians carefully check offsets. But even with an experienced hand, accuracy is a constant battle against physical limitations.

Over long spans, wire sag is unavoidable and must be manually accounted for. Any correction requires the wire to be reset, and each new adjustment demands another full round of measurements. For large turbines, this process can take days—bearing centerline corrections alone require up to 72 hours, and a full alignment cycle can stretch to 126 hours. And despite the effort involved, piano wire alignment is only as precise as the technician interpreting the results.

The Trade-Offs of a Legacy Method

While piano wire remains in use, its limitations are hard to ignore:

- Labor-Intensive Setup: Positioning the wire precisely in the bore centerline is tedious and requires high skill.

- Sag and Error: Over long distances, wire sag introduces distortions that must be manually compensated for.

- Technician-Dependent Accuracy: Measurement consistency depends on the experience and technique of the operator.

- Time-Consuming: Large-scale bore alignments can take up to 126 hours, with multiple iterations required.

- Limited Documentation: Readings are recorded manually, making traceability and quality control difficult.

For all its drawbacks, piano wire has persisted for a reason—it’s familiar, widely understood, and requires no specialized hardware. But as turbines grow larger, tolerances tighten, and maintenance schedules demand faster turnarounds, how sustainable is this approach?

Optical Alignment: A Marginal Improvement

Optical methods, while more advanced than piano wire, still come with significant challenges. Systems like telescopic sighting devices and autocollimators provide a more precise reference line, but they remain highly dependent on technician expertise. Setup is meticulous, requiring perfect alignment of optical targets and careful calibration to avoid measurement drift.

Accuracy varies, typically ranging from ±0.05 mm to ±0.1 mm, depending on the instrument and the skill of the operator. And while optical tools eliminate wire sag, they introduce their own set of issues. Light conditions, vibration, and even temperature fluctuations can affect measurements, requiring ongoing adjustments to maintain accuracy.

Another drawback is error accumulation. Each time the optical station is moved, a minimum error of 0.1 mm is introduced, which then carries over into subsequent readings, making long-distance measurements increasingly unreliable.

So while optical methods reduce some of the inefficiencies of wire-based alignment, they don’t fully solve the industry’s biggest challenge: achieving precision without extensive manual effort.

That’s where laser-based systems come in.

Laser Alignment: A Fundamental Shift

The real difference between laser-based alignment and traditional methods isn’t just precision—it’s how alignment is approached. With piano wire and optical tools, the process is inherently reactive: measure, adjust, repeat. Each cycle introduces a potential for error, whether from wire sag, technician variability, or environmental conditions. Laser alignment changes this dynamic entirely.

Instead of working around physical constraints, lasers provide a fixed, distortion-free reference across long distances. More importantly, they allow for proactive alignment—measurements aren’t just a final check but a real-time guide, helping technicians correct deviations as they go.

With that shift comes a different way of working. Technicians aren’t just measuring; they’re actively aligning. The process moves from iterative correction to continuous optimization, reducing rework and cutting down alignment time from days to hours. A full bore alignment that once took up to 126 hours with piano wire can now be completed in just 8–10 hours. And setup, which required two hours with manual methods, now takes as little as 15 minutes.

How CentrAlign Ultra is Changing the Equation

Systems like CentrAlign Ultra are built around this shift. Developed for high-precision bore alignment in steam and gas turbines, compressors, and other rotating machinery, it replaces traditional methods with laser-based measurement and real-time digital feedback. Unlike wire or optical tools, CentrAlign Ultra doesn’t just measure bore alignment—it provides true bore centerline positioning, eliminating sag from wire-based methods and actively compensating for laser drift over long distances.

A key component of this system is CentrAlign’s patented bracket design, engineered for both magnetic and non-magnetic bores. These brackets allow for tops-on or tops-off configurations, adapting to various turbine and machinery setups. Unlike traditional alignment methods that require painstaking manual adjustments, CentrAlign Ultra’s brackets hold the laser and sensor in a stable, repeatable position—ensuring accuracy without technician-induced misalignment.

Each bracket features a fixed base that locks securely into place, while a rotating sensor holder ensures precise centering. This allows technicians to rotate the sensor freely within the bore while maintaining a consistent reference point, eliminating mechanical sag and manual positioning errors that were unavoidable with piano wire and optical tools. The system supports bore diameters ranging from 120 mm to 5000 mm, making it adaptable to a wide range of turbine and industrial applications.

Additionally, with wireless data transmission and automated calculations, CentrAlign Ultra eliminates the need for manual recording and iterative corrections. Measurements are displayed in real time, allowing technicians to adjust alignment instantly rather than going through repeated setup cycles. This efficiency translates directly into time savings—bearing centerline corrections that once took 72 hours can now be completed in just 3.

For large-scale turbine maintenance, this isn’t just a convenience—it’s a necessity. With bore distances reaching up to 166 feet, traditional alignment tools introduce too much uncertainty and accumulated error over long spans. CentrAlign Ultra’s laser-guided brackets and real-time drift compensation ensure a consistent, high-precision reference line, achieving accuracy in the range of ±0.005 mm to ±0.02 mm.

But this shift isn’t just about one system—it’s about a fundamental change in how the industry approaches bore alignment. The question is no longer whether laser-based systems work, but whether traditional methods can keep up with modern demands.

Comparing Bore Alignment Methods

| Piano Wire Alignment | CentrAlign Ultra | |

| Setup Time | 2 hours | 15 Minutes |

| Establishing Benchmarks | 2 hours manual setup |

Instant computed digitally |

| Wire Sag/Distortion | Requires manual corrections | Not applicable (laser-straight reference) |

| First Alignment Measurement | 3 hours requires wire removal |

1 hour continuous measurement |

| Bearing Centerline Correction | 72 hours shimming, lapping, resetting wire |

3 hours real-time adjustments |

| First Diaphragm Correction | 10 hours grinding & realignment |

Corrected alongside measurement |

| Second Alignment Check | 3 hours wire must be reset |

1 hour no need to remove the laser |

| Second Correction Cycle | 10 hours | Minimal additional time as laser is already set up |

| Rechecking Adjustment after Diaphragm Installation | 8 hours wire must be reset again |

1 hour digital validation |

| Third Reading of Diaphragms | 3 hours | 1 hour |

| Total Time for Full Alignment | 126 hours | 8–10 hours |

The Industry at a Crossroads

For decades, bore alignment has been a test of patience and precision. Traditional methods—piano wire, micrometers, and optical sighting devices—were the best tools available, but they relied on skilled hands, repeated measurements, and manual interpretation.

That approach worked when turbines were smaller, tolerances were looser, and downtime wasn’t as costly. But today, with bore distances stretching up to 166 feet, micron-level accuracy required, and every hour of downtime translating to lost revenue, the industry is facing a new reality: alignment needs to be faster, more repeatable, and less technician-dependent.

Laser-based systems like CentrAlign Ultra aren’t just a better tool—they represent a fundamental shift in how bore alignment is performed. Real-time measurements replace iterative corrections. Wireless data replaces handwritten logs. Automated centerline positioning replaces manual adjustments. What once took 126 hours now takes 8 to 10.

The benefits are clear. But change doesn’t happen overnight. Traditional methods have been the foundation of bore alignment for generations, and shifting away from them isn’t just about adopting new technology—it’s about rethinking what’s possible.

For many maintenance teams, the shift has already begun. The question is no longer if laser-based alignment will replace traditional methods—but when.